- Call Us for help!

- +91 9819742205

- Mail Us

- Brasslinkinternational@gmail.com

Manufacturer,Stockist and Valve of Brass Ball Valve

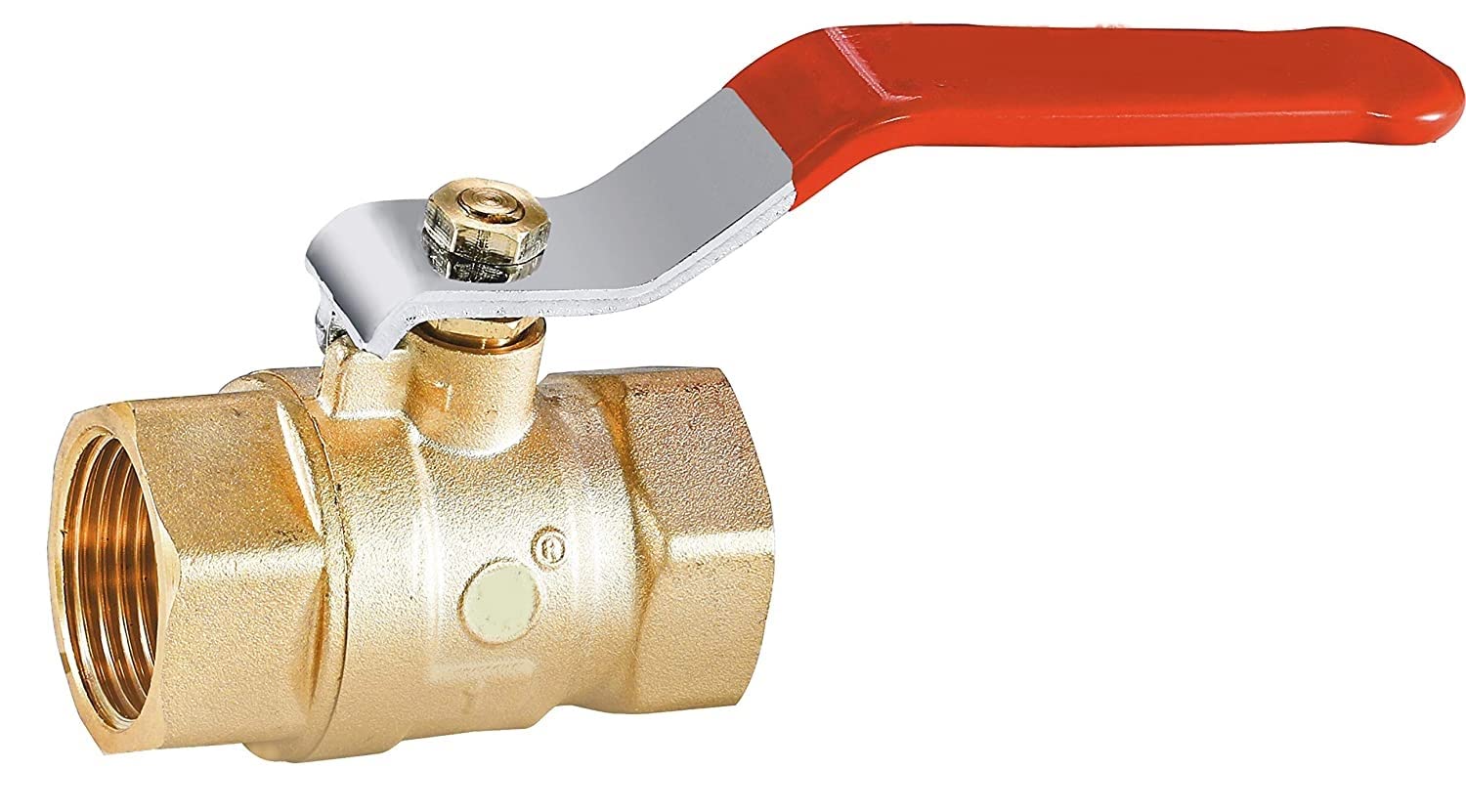

A Brass Ball Valve is a crucial component in plumbing and industrial piping systems, providing reliable flow control. Made from high-quality brass, these valves are resistant to corrosion and offer durability even in challenging conditions. Their compact design makes them ideal for both residential and commercial applications. The ball inside the valve allows for smooth operation, ensuring precise control of liquid or gas flow. With a simple quarter-turn operation, these valves can quickly stop or allow flow. Brass Ball Valves are commonly used in water, oil, and gas pipelines. Their maintenance is minimal, making them a cost-effective solution for long-term use.

Brass Ball Valves are favored for their versatility and robust construction. The brass material provides excellent mechanical strength and can withstand high pressure and temperature variations. These valves are typically available in various sizes, fitting both small and large pipe diameters. The ball mechanism inside the valve ensures minimal leakage and maximum sealing efficiency. Many models feature a chrome-plated or nickel-plated finish to further resist wear and tear. Brass Ball Valves are often used in heating, ventilation, and air conditioning (HVAC) systems. Their ease of installation makes them suitable for both DIY and professional setups.

The design of a Brass Ball Valve ensures smooth and effortless operation. The valve can rotate 90 degrees to fully open or close, providing fast flow control. Brass Ball Valves come in both threaded and flanged connections, catering to different piping systems. The handle is ergonomically designed for a firm grip, even when wet or oily. Some variants include a locking mechanism to prevent accidental operation. These valves are also capable of handling corrosive fluids, depending on the brass alloy used. Their long service life makes them an economical choice for industries and households alike.

In addition to their functionality, Brass Ball Valves are environmentally friendly due to the recyclability of brass. The manufacturing process ensures minimal waste and long-term durability, reducing the need for frequent replacements. These valves are suitable for potable water systems, complying with health and safety standards. They can operate under various pressure ranges, from low to high-pressure systems. Brass Ball Valves also offer reliable performance in both hot and cold water applications. Many industrial applications rely on these valves for chemical processing and fluid control. Overall, their adaptability makes them a standard choice in many sectors.

The installation of Brass Ball Valves is straightforward, requiring minimal tools. Threaded valves can be easily connected using Teflon tape or pipe sealant. Flanged valves are bolted securely, ensuring no leakage at the joint. It is important to select the correct valve size to match the pipe diameter for optimal flow efficiency. Brass Ball Valves are highly resistant to scaling and mineral buildup, making them ideal for hard water systems. Regular inspection and occasional lubrication of the handle can further extend their service life. The valve's compact design allows it to fit into tight spaces without compromising functionality.

Brass Ball Valves are categorized based on pressure ratings, sizes, and connection types. Standard models handle medium pressure applications, while industrial-grade versions support high-pressure operations. Full-port brass ball valves allow maximum flow, reducing pressure drop in pipelines. Reduced-port versions are used where flow regulation is necessary. Some valves include a T-handle or lever handle, depending on user preference. Many manufacturers also offer custom solutions for specific industrial needs. Their versatility and efficiency make them widely used in plumbing, manufacturing, and chemical processing industries.

Maintenance of Brass Ball Valves is simple yet essential for optimal performance. Periodic cleaning prevents debris from interfering with the ball mechanism. Lubricating the stem ensures smooth handle rotation and prevents seizing. Inspecting seals and gaskets helps maintain leak-proof operation. Brass Ball Valves are less prone to corrosion than other metal valves, but exposure to aggressive chemicals should be avoided. These valves can last decades if installed and maintained properly. Choosing the right brass alloy, such as C37700 or C46400, ensures resistance to wear and high-pressure performance. Proper handling during installation prevents damage to internal components.

The advantages of Brass Ball Valves extend beyond durability and reliability. They provide precise flow control, quick shut-off, and a high-pressure rating. These valves are corrosion-resistant, making them suitable for water, oil, and gas pipelines. They are versatile and available in various sizes, pressure ratings, and connection types. Their simple design allows easy operation and maintenance. Brass Ball Valves are also aesthetically pleasing due to their polished finish. These factors collectively make them a preferred choice in residential, commercial, and industrial settings.

Specification Of Brass Ball Valve

| Specification | Details |

|---|---|

| Material | High-quality Brass (C37700, C46400) |

| Valve Type | Ball Valve |

| Connection Type | Threaded / Flanged / Soldered |

| Size Range | 1/4" to 4" (6mm to 100mm) |

| Pressure Rating | Up to 1000 PSI (depending on size) |

| Temperature Range | -20°C to 150°C (-4°F to 302°F) |

| Operation | Quarter-turn handle |

| Sealing Material | PTFE / Teflon |

| End Connection | Female Threaded / Male Threaded / Flanged |

| Applications | Water, Oil, Gas, HVAC, Industrial Pipelines |

| Standards | ISO 9001, ASTM B16, EN 12165 |

Brass Ball Valves are used in a wide range of applications. In residential plumbing, they control water flow in kitchens, bathrooms, and irrigation systems. In industrial settings, they manage oil, gas, and chemical pipelines. They are also used in HVAC systems, ensuring proper circulation and temperature control. Food and beverage industries utilize sanitary brass valves for safe fluid handling. Marine and shipbuilding industries employ these valves due to their corrosion resistance in saltwater environments. Their adaptability and efficiency make them suitable for nearly every sector requiring fluid control.

When selecting a Brass Ball Valve, several factors must be considered. Material quality is paramount; high-quality brass ensures durability and resistance to corrosion. The valve size should match the pipe diameter to avoid pressure loss. Operating pressure and temperature limits must be checked to ensure compatibility. The type of connection—threaded, flanged, or soldered—depends on the piping system. Additional features, such as locking handles or Teflon seats, enhance functionality. Certified valves that comply with international standards are preferred for safety and reliability. These considerations guarantee optimal performance and longevity.

Brass Ball Valves are also energy-efficient due to their low resistance to flow. Full-port designs allow liquids and gases to pass freely, reducing pump energy consumption. They contribute to water conservation by minimizing leaks and drips. These valves are environmentally friendly, as brass is recyclable and sustainable. Compared to other materials, brass maintains its integrity under extreme temperatures and pressures. The smooth internal surface reduces friction and wear on the piping system. This makes Brass Ball Valves a cost-effective solution over the lifespan of the system.

Chemical Properties Of Brass Ball Valve

| Element | Percentage (%) | Purpose / Effect |

|---|---|---|

| Copper (Cu) | 60 - 70% | Provides corrosion resistance, strength, and thermal conductivity |

| Zinc (Zn) | 30 - 40% | Increases hardness, machinability, and durability of the valve |

| Lead (Pb) | 0.5 - 3% | Enhances machinability, especially in threaded connections |

| Iron (Fe) | ≤ 1% | Improves strength and corrosion resistance |

| Nickel (Ni) | Optional 0.5 - 2% | Enhances corrosion resistance and appearance |

| Manganese (Mn) | ≤ 1% | Increases strength and hardness |

| Others | Trace | Minor elements that improve machinability and stability |

Technological advancements have improved the performance of Brass Ball Valves. Modern manufacturing techniques ensure precise machining of the ball and seat, eliminating leakage. Some valves now include PTFE or reinforced seats for enhanced sealing. Automation options, such as electric or pneumatic actuators, allow remote operation. These innovations expand the usability of Brass Ball Valves in smart buildings and industrial automation. Improved corrosion-resistant coatings further extend the valve’s lifespan. By integrating technology, Brass Ball Valves meet the increasing demand for efficiency and reliability in fluid control.

Safety is a key benefit of Brass Ball Valves. Their robust design ensures leak-proof operation even under high pressure. They provide fast shut-off capabilities, crucial during emergencies or maintenance. The ergonomic handle reduces operator fatigue and prevents mishandling. Lockable handles prevent unauthorized access in industrial environments. Proper installation and periodic inspection ensure safe operation. Using high-quality brass minimizes the risk of cracks or failure. These safety features make Brass Ball Valves ideal for both household and industrial applications.

The market for Brass Ball Valves is growing due to increasing demand in residential, commercial, and industrial sectors. Manufacturers offer a wide range of sizes, pressure ratings, and connection types. Customization is available for specialized industrial requirements. Their durability, reliability, and low maintenance needs make them a preferred choice. Many suppliers provide warranties and certifications for quality assurance. Technological improvements continue to enhance their performance and efficiency. The combination of affordability, longevity, and versatility ensures Brass Ball Valves remain a staple in fluid control solutions.

Mechanical properties Properties Of Brass Ball Valve

| Property | Typical Value | Unit | Description |

|---|---|---|---|

| Tensile Strength | 350 - 500 | MPa | Maximum stress the material can withstand while being stretched or pulled |

| Yield Strength | 200 - 300 | MPa | Stress at which the material begins to deform plastically |

| Hardness (Brinell) | 55 - 100 | HB | Resistance to surface indentation and wear |

| Elongation | 15 - 35 | % | Material’s ability to stretch before breaking |

| Impact Strength | 35 - 50 | J | Resistance to sudden shock or impact |

| Density | 8.4 - 8.7 | g/cm³ | Mass per unit volume, affects weight and stability of the valve |

| Shear Strength | 200 - 300 | MPa | Ability of the material to resist sliding failure along a plane |

| Modulus of Elasticity | 100 - 110 | GPa | Measure of material stiffness under stress |

Application:

- Electrical Industry

- HVAC Industry

- Ball Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Frequently Asked Questions (FAQs)

Q1: What is a Brass Ball Valve?

A Brass Ball Valve is a valve that uses a spherical ball to control the flow of liquids or gases. It is made from high-quality brass for durability and corrosion resistance, providing reliable shut-off and flow control.

Q2: What are the main applications of Brass Ball Valves?

Brass Ball Valves are used in plumbing, water supply systems, oil and gas pipelines, HVAC systems, and various industrial applications requiring reliable flow control.

Q3: How do I operate a Brass Ball Valve?

These valves operate using a quarter-turn handle. Turning the handle 90 degrees opens or closes the valve, allowing for quick flow control and shut-off.

Q4: What types of connections are available for Brass Ball Valves?

Brass Ball Valves come with threaded (male/female), flanged, and soldered connections to suit different piping systems and installation requirements.

Q5: How do I maintain a Brass Ball Valve?

Maintenance is minimal. Periodically check for leaks, clean debris, and lubricate the handle if necessary. High-quality brass ensures long service life with minimal upkeep.

Q6: Can Brass Ball Valves be used for hot water?

Yes, most Brass Ball Valves can handle temperatures up to 150°C (302°F), making them suitable for hot water applications as well as cold water systems.

Q7: Are Brass Ball Valves corrosion-resistant?

Yes, brass is highly resistant to corrosion and scaling. However, exposure to aggressive chemicals should be avoided to ensure long-term performance.

Our valuable Products

Brass-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Check-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Brass-Valves-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Brass-Water-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Valve-Fittings-Manufacturer-Stockist-Exporter.html,

Copper-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Check-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Refrigeration-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Forged-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Forged-Copper-Valve-Manufacturer-Stockist-Exporter.html,

High-Pressure-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Lead-Free-Brass-valve-Manufacturer-Stockist-Exporter.html,

Countries we have exported our products to:

manufacturer stockist and Valve of Brass Ball Valve in mumbai,manufacturer stockist and Valve of Brass Ball Valve in India,manufacturer stockist and Valve of Brass Ball Valve in United Arab Emirates,manufacturer stockist and Valve of Brass Ball Valve in Saudi Arabia,manufacturer stockist and Valve of Brass Ball Valve in Kuwait,manufacturer stockist and Valve of Brass Ball Valve in Bahrain Qatar,manufacturer stockist and Valve of Oman, manufacturer stockist and Valve of Brass Ball Valve in USA, Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.