- Call Us for help!

- +91 9819742205

- Mail Us

- Brasslinkinternational@gmail.com

Manufacturer,Stockist and Exporter of Brass Valve Supplier

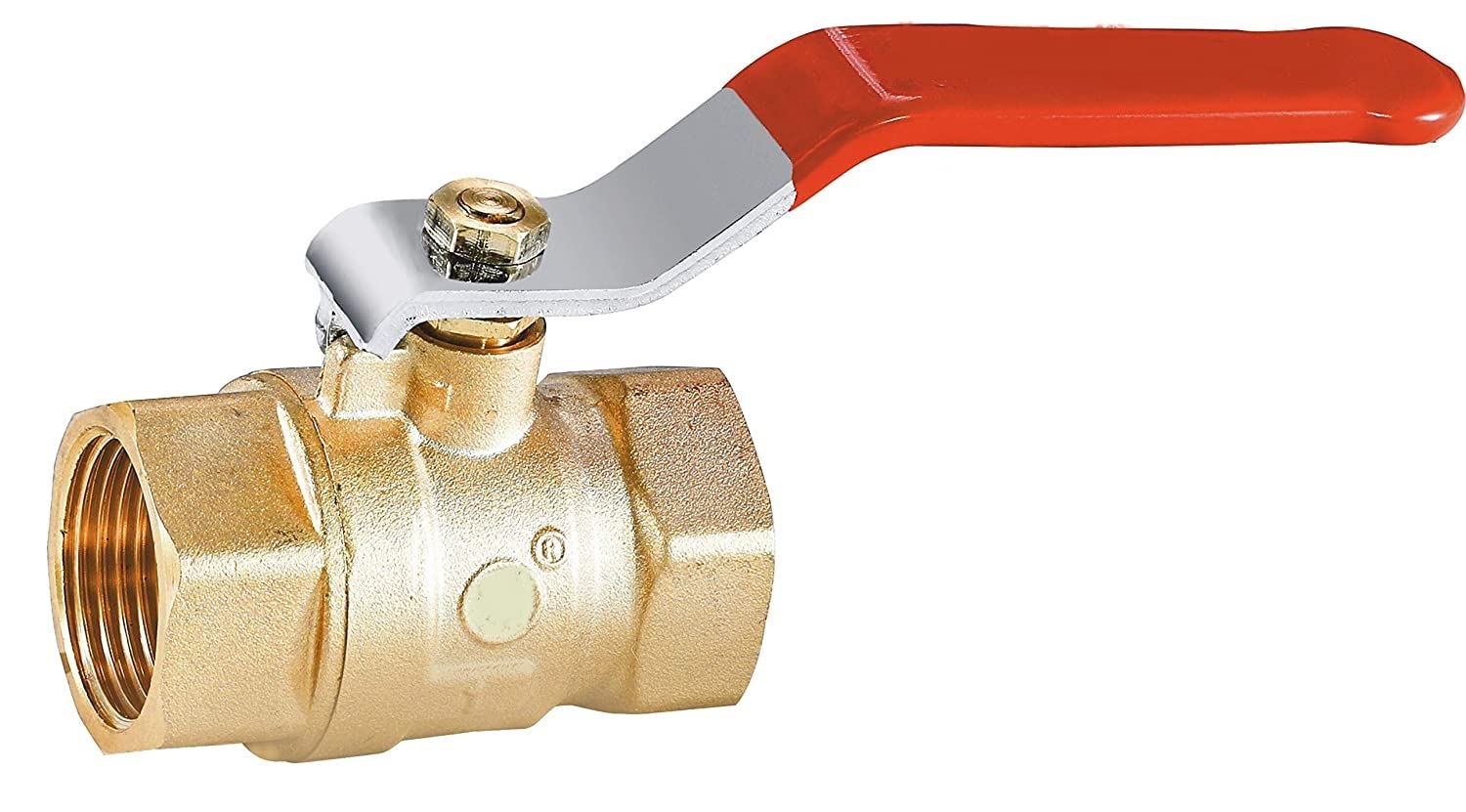

A reliable brass valve supplier plays a critical role in supporting industrial flow-control systems, plumbing networks, and HVAC installations. The quality of these valves determines long-term performance and maintenance demands in pipelines. Suppliers must provide valves that resist corrosion, maintain sealing integrity, and withstand temperature changes. Their broad inventory often includes ball valves, gate valves, globe valves, and safety valves. Clients ranging from construction firms to oil and gas operators seek dependable supply chains. A strong supplier ensures consistent availability of stock in multiple sizes and pressure ratings. Timely communication and technical guidance form the foundation of customer trust. The best suppliers combine product competence with engineering expertise.

Brass, as an alloy of copper and zinc, offers excellent machinability and thermal performance. Its natural resistance to mineral buildup makes it ideal for valves in water distribution systems. Unlike plastic or iron, brass valves retain dimensional stability when exposed to fluctuating pressures. They exhibit superb sealing properties when paired with PTFE or rubber components. A competent brass valve supplier sources alloys that meet ASTM, EN, or IS standard certifications. This ensures uniform metallurgical composition and predictable service performance. Engineered brass valves prevent leakage, contamination, and system downtime. In mission-critical systems, these advantages enhance both safety and efficiency.

The product range of a brass valve supplier commonly spans manual and automated mechanisms. Ball valves deliver quick shut-off control, while gate valves manage steady flow regulation. Check valves prevent unwanted backflow, protecting pumps and sensitive equipment. Angle and needle valves allow fine adjustments in pressure and flow. Industrial buyers often request valves designed for cryogenic fluids, chemicals, or high-temperature steam. Suppliers who maintain specialty configurations broaden their appeal to engineers and OEM clients. Each model must be validated against specific operational environments. Performance consistency is achieved through advanced manufacturing and precision testing.

Manufacturing practices significantly influence the reliability of brass valves. Top suppliers collaborate with factories equipped with CNC machining, forging presses, and calibrated inspection tools. Precise production methods help maintain smooth bore passageways and uniform thread geometry. Heat-treatment schedules ensure strong microstructure and resistance to fatigue. Quality control protocols check dimensional tolerances, seat finishes, and sealing surfaces. Pressure testing is typically performed using hydrostatic or pneumatic systems. Batch traceability allows users to follow material origins and process history. These steps guarantee a high-integrity product ready for industrial deployment.

Industrial clients prefer suppliers who deliver clear documentation and compliance support. Datasheets, CAD drawings, and operating manuals simplify engineering integration. Certificates such as ISO 9001 reinforce confidence in controlled manufacturing processes. Third-party certifications like CE, RoHS, or WRAS further validate valve suitability. Suppliers who maintain digital catalogs offer faster cross-reference ability. Procurement teams benefit from organized SKUs and performance specifications. Documentation reduces compatibility risk during installation. A professional supplier understands the importance of technical transparency.

A major value factor in brass valve sourcing is durability under real-world stress. Valves must resist wear caused by friction, water impurities, and chemical exposure. Electro-plated or nickel-coated brass offers enhanced protection against harsh media. Internal surfaces must maintain tight tolerances for long lasting smooth operation. Thermal stability prevents warping at elevated temperatures. Continuous flow cycles introduce vibration loads that degrade lesser materials. Robust brass compositions mitigate deformation and leakage. The result is longer service life and reduced maintenance burden.

Brass valve suppliers often serve diversified industry verticals. The plumbing sector demands compact valves with premium sealing and ease of installation. HVAC systems require balanced control to optimize energy efficiency. Chemical processing demands valves that resist reactive fluids and maintain flow reliability. Agricultural irrigation networks prioritize endurance against mineral buildup and sediment. Marine users seek corrosion resistance in salty environments. Fire-protection systems require compliance with strict safety certifications. A good supplier adapts offerings to these industry-specific conditions.

Global suppliers differentiate themselves through logistics and fulfillment capabilities. Large-scale procurement cycles rely on predictable inventory and rapid dispatch. Some suppliers maintain regional warehouses to shorten transit time. Bulk packaging formats protect valve integrity during shipping. Exporters comply with customs documentation, HS codes, and destination regulations. Clients appreciate transparent delivery tracking and proactive notifications. Project managers benefit from batch-based shipment scheduling. Seamless logistics reduce delays in construction or production cycles.

Specification Of Brass Valve Supplier

| Specification | Details |

|---|---|

| Material | High-quality brass (C83600 / C46400 / CW617N) — lead-free options available |

| Standards & Specs | ASTM B124 / EN 12165 / IS 319 / BS EN where applicable |

| Available Valve Types | Ball, Gate, Globe, Check, Angle, Needle, Stopcock |

| Size Range | 1/8" — 4" (DN6 — DN100) (custom sizes on request) |

| Pressure Rating | PN10 / PN16 / 150 PSI / 300 PSI (depends on type and design) |

| Temperature Range | -20°C to +120°C (higher-temp variants available) |

| End Connections | Threaded (BSP / NPT), Socket Weld, Flanged, Solder, Compression |

| Trim Materials | Brass, Stainless Steel (SS304/SS316) seats & stems, PTFE / reinforced PTFE |

| Seat & Seal Material | PTFE, NBR, EPDM, Viton — selection per fluid compatibility |

| Finish / Plating | Natural brass, Nickel-plated, Chrome-plated, Passivated, Lacquered |

| Testing | Hydrostatic & pneumatic testing, leakage class verification, dimensional inspection |

| Certifications | ISO 9001, WRAS / NSF (potable water) options, CE on request |

| Typical Applications | Plumbing, HVAC, waterworks, irrigation, chemical handling, marine, fire protection |

| Packaging & Delivery | Individual cartons, bulk crates, export-ready pallets; lead times depend on stock & order size |

| Warranty | Standard 12-month manufacturer warranty (extended warranty/options available) |

| Customization | OEM branding, custom packaging, special alloys, bespoke machining on request |

After-sales support distinguishes exceptional brass valve suppliers. Technical teams assist with installation procedures and compatibility issues. Field professionals handle inspection and testing guidance for commissioning. Replacement components—such as seals, handles, or stem assemblies—should be readily available. Warranty policies reflect supplier confidence in product longevity. Responsive customer service prevents downtime and operational loss. Training modules help engineers understand maintenance strategies. The customer relationship extends beyond a one-time transaction.

Price competitiveness is an important but not exclusive purchasing factor. Cheaper valves may compromise on alloy purity, machining accuracy, or test standards. Professional suppliers focus on total cost of ownership rather than purchase price. A well-engineered brass valve reduces water loss, repair demands, and replacement frequency. OEM customers consider lifecycle economics and procurement stability. Strategic suppliers offer tiered pricing based on volume, contract duration, or custom builds. This balance allows clients to manage budgets without sacrificing safety. Economic value arises from dependable performance over time.

Advanced suppliers integrate digital tools into their procurement ecosystem. Online configurators allow engineers to select body types, end connections, and pressure classes. Some offer ERP/CRM integrations for automated purchase orders. Digital inventory dashboards provide real-time stock visibility. Document libraries store MSDS, pressure ratings, and installation guides. Virtual quoting engines speed up response time for inquiries. Such systems reduce administrative effort and accelerate project planning. The modern supplier embraces technology to deliver convenience.

Chemical Properties Of Brass Valve Supplier

| Element | C83600 (Lead Bronze) | C46400 Naval Brass | CW617N (EN 12165) |

|---|---|---|---|

| Copper (Cu) | 84.0–86.0% | 59.0–63.0% | 57.0–59.0% |

| Zinc (Zn) | 4.0–6.0% | 40.0–41.0% | 39.0–41.0% |

| Lead (Pb) | 4.0–7.0% | ≤0.10% | 2.0–3.5% |

| Tin (Sn) | 4.0–6.0% | 0.7–1.0% | ≤0.30% |

| Iron (Fe) | ≤0.10% | 0.05–0.20% | ≤0.30% |

| Manganese (Mn) | ≤0.20% | 0.2–0.6% | ≤0.20% |

| Nickel (Ni) | ≤1.0% | ≤0.30% | ≤0.30% |

| Others | Max 0.5% total (impurities) | Max 0.5% total (impurities) | Max 0.3% total (impurities) |

Custom fabrication services add versatility to a brass valve supplier’s portfolio. Clients often need specialized threads, bore diameters, or actuation systems. Prototype development supports OEM innovation and R&D. Machining centers can produce low-volume or high-precision components. Laser engraving helps trace product batches and prevent counterfeit issues. Custom packaging ensures compatibility with industry-specific environments. Engineering teams collaborate with buyers to refine performance specifications. Customization strengthens supplier value in competitive markets.

Environmental responsibility is increasingly important in sourcing choices. Ethical suppliers procure raw brass from regulated, sustainable supply chains. Recycling initiatives help reclaim metal waste during machining. Lead-free brass formulations address potable water safety standards. Energy-efficient manufacturing reduces carbon footprint. Certificates like ISO 14001 validate eco-conscious processes. Clients evaluate sustainability as part of vendor selection. Responsible suppliers align technical quality with environmental stewardship.

Market longevity demonstrates supplier reliability. Companies with decades of experience understand sector challenges and technical evolution. A strong supplier builds long-term partnerships rather than transactional sales. They anticipate new standards and proactively upgrade product lines. Historical knowledge accelerates troubleshooting and compatibility checks. Reputation spreads through client testimonials and project portfolios. Industry presence enables strategic procurement confidence. Seasoned suppliers guide buyers through complex technical decisions.

Mechanical properties Properties Of Brass Valve Supplier

| Property | C83600 (Lead Bronze) | C46400 Naval Brass | CW617N (EN 12165) |

|---|---|---|---|

| Tensile Strength | ~276–310 MPa | ~350–480 MPa | ~330–420 MPa |

| Yield Strength | ~103–140 MPa | ~145–210 MPa | ~140–200 MPa |

| Elongation (%) | 10–20% | 20–35% | 25–40% |

| Hardness (HB) | 70–90 HB | 120–150 HB | 80–115 HB |

| Modulus of Elasticity | ~105–115 GPa | ~98–110 GPa | ~100–110 GPa |

| Impact Strength (Izod) | ~14–18 J | ~20–25 J | ~18–22 J |

| Density | 8.3–8.7 g/cm³ | 8.3–8.5 g/cm³ | 8.3–8.6 g/cm³ |

| Temperature Resistance | -20°C to 200°C | -30°C to 220°C | -20°C to 180°C |

Application:

- Electrical Industry

- HVAC Industry

- Plumbing Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Frequently Asked Questions (FAQs)

1. What types of brass valves do you supply?

We supply a complete range of brass valves including ball valves, gate valves, check valves, globe valves, angle valves, needle valves, and stopcocks. Custom designs, OEM branding, and specialized end connections are also available.

2. Are your brass valves suitable for potable water applications?

Yes, we offer lead-free brass and WRAS/NSF certified valves designed for drinking water systems. These comply with relevant safety and hygiene standards to ensure long-term reliability and water purity.

3. What pressure ratings do your brass valves support?

Our standard brass valves are available in PN10, PN16, 150 PSI, and 300 PSI pressure classes. Higher ratings may be provided depending on valve type, material configuration, and application requirements.

4. Do you offer customized or OEM brass valve solutions?

Yes. We provide custom machining, special sizes, thread types (BSP/NPT/METRIC), coatings, and engraving. OEM packaging, branding, and private label manufacturing options are available for bulk and distributor orders.

5. What industries commonly use your brass valves?

Our brass valves are widely used in plumbing, HVAC, irrigation, fire protection, marine systems, water treatment, chemical handling, oil & gas distribution, and general industrial fluid control.

6. How are your brass valves tested before delivery?

Each valve undergoes dimensional verification, sealing inspection, and hydrostatic/pneumatic pressure testing. Quality control is conducted under ISO 9001 standards to ensure leak-free and defect-free performance.

7. What warranty do you provide on brass valves?

We offer a standard manufacturer's warranty of 12 months from the date of delivery. Extended warranties may be available depending on project scope, operating environment, and contract terms.

Our valuable Products

Brass-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Check-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Brass-Valves-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Brass-Water-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Valve-Fittings-Manufacturer-Stockist-Exporter.html,

Copper-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Check-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Refrigeration-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Forged-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Forged-Copper-Valve-Manufacturer-Stockist-Exporter.html,

High-Pressure-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Lead-Free-Brass-valve-Manufacturer-Stockist-Exporter.html,

Countries we have exported our products to:

manufacturer stockist and exporter of Brass Valve Supplier in mumbai,manufacturer stockist and exporter of Brass Valve Supplier in India,manufacturer stockist and exporter of Brass Valve Supplier in United Arab Emirates,manufacturer stockist and exporter of Brass Valve Supplier in Saudi Arabia,manufacturer stockist and exporter of Brass Valve Supplier in Kuwait,manufacturer stockist and exporter of Brass Valve Supplier in Bahrain Qatar,manufacturer stockist and exporter of Oman, manufacturer stockist and exporter of Brass Valve Supplier in USA, Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.