- Call Us for help!

- +91 9819742205

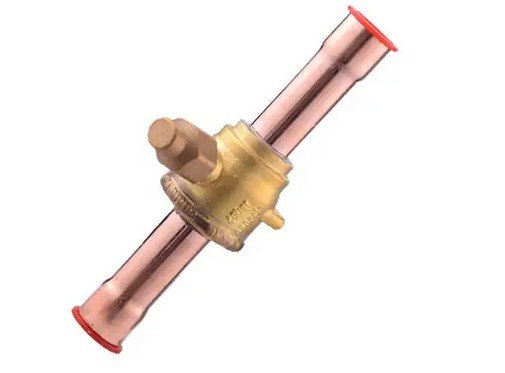

Manufacturer,Stockist and Exporter of Copper Refrigeration Valve

Copper refrigeration valves are essential components in HVAC and commercial cooling applications. They regulate and control refrigerant flow during system operation. Copper as a base material provides natural corrosion resistance in harsh environments. The valves are manufactured with precision to withstand high pressure cycles. Their thermal conductivity supports efficient system balance during temperature changes. Copper valves are compatible with R134a, R404A, R410A, and similar refrigerants. Professionals use them in supermarkets, cold rooms, and transport cooling systems.

One of the primary advantages of copper refrigeration valves is durability. Unlike steel or low-grade alloys, copper resists long-term moisture and chemical exposure. The valve bodies maintain structural integrity even in low-temperature conditions. Service engineers prefer copper fittings for brazing and soldering compatibility. Minimal oxidation over years of use reduces maintenance cost. Pipe connections remain leak-free due to stable thermal expansion characteristics. This makes copper valves suitable for continuous duty refrigeration lines.

Copper refrigeration valves are commonly installed at critical system junctions. They provide shutoff and isolation during service or compressor replacement. Ball valves enable quick on/off control with minimal flow resistance. Service valves allow direct refrigerant charging and vacuuming operations. Schrader valves support pressure monitoring without system disassembly. Installation technicians rely on them to maintain safe working conditions. Their compact design fits both small appliances and industrial systems.

Manufacturers design copper refrigeration valves with smooth internal passages. This prevents turbulence and reduces energy loss in refrigerant circulation. Flow optimization ensures compressors work with minimal load variation. Over time, consistent flow characteristics improve system life expectancy. Rounded port geometries minimize refrigerant flash and pressure drop. Uniform surface finishing also discourages oil film accumulation. All these features contribute to stable cooling performance.

Copper has an excellent balance of strength and malleability. This characteristic simplifies forming and machining valve bodies. Thin-wall brazed components can perform as reliably as thick castings. Copper valves typically maintain pressure ratings above industrial standards. Quality control includes hydrostatic pressure testing before shipment. Engineers verify crack resistance using fatigue cycling methods. Customers benefit from robust valves suitable for demanding applications.

In refrigeration systems, temperature differentials are extreme. Copper valves absorb and distribute heat without sudden deformation. Their metal structure resists low-temperature brittleness. Even at sub-zero levels, sealing surfaces stay stable. This protects elastomer O-rings and prevents leakage. Long-term behavior is critical for commercial freezing rooms. Copper’s thermal consistency is a key selection factor.

Refrigeration tubing often requires brazing during installation. Copper refrigeration valves are manufactured with brazable ends for convenience. This ensures strong permanent joints without mechanical compression fittings. Technicians apply silver-bearing brazing rods to achieve airtight seals. High-temperature brazed joints perform excellently in vibration environments. Copper-to-copper bonding enhances reliability under constant cycling. This construction method remains industry standard worldwide.

Many copper refrigeration valves include integrated service ports. These ports allow technicians to flush, test, or recover refrigerant. Quick-connect access reduces downtime during service visits. Pressure gauges can be attached without removing the valve. Such features improve workplace safety and regulatory compliance. Proper service access enhances long-term system life. Cooling operations remain uninterrupted during routine maintenance.

Specification Of Copper Refrigeration Valve

| Specification Parameter | Details |

|---|---|

| Material | High-Grade Copper (C12200 / C11000) |

| Valve Type | Ball Valve / Service Valve / Schrader Valve / Needle Valve |

| Operating Temperature | -40°C to +150°C (Depending on valve design) |

| Pressure Range | Up to 4.0 MPa (580 PSI) Working Pressure |

| Connection Type | Brazed Ends / Flare Ends / Compression Ends |

| Refrigerant Compatibility | R134a, R22, R404A, R407C, R410A, R600a, CO₂ |

| Leakage Rate | < 1×10⁻⁵ mbar·L/s (Helium Tested) |

| Working Medium | Refrigerant Gas / Refrigeration Oil |

| Sealing Material | HNBR / PTFE / FKM |

| Port Diameter | 1/4" – 1 1/2" (Customizable) |

| Installation Method | Brazing / Welding / Flare Tool Fitting |

| Body Surface Finish | Polished / Oxidation-Resistant |

| Design Standard | ISO 5149 / ASHRAE / CE / OEM Standards |

| Usage Application | HVAC, Commercial Cooling, Freezer Systems, Industrial Refrigeration |

Copper valves are offered in multiple configurations. Straight pattern valves suit linear piping layouts. Angle pattern valves support tight equipment spaces. Two-way ball valves isolate components completely. Needle-type expansion valves provide fine refrigerant control. Different valve structures meet varying flow velocity requirements. System designers choose based on load and installation geometry.

The refrigeration industry emphasizes leak-proof infrastructure. Copper’s metallurgical behavior helps prevent micro-fractures. Valve seats are precision-ground for long-term sealing accuracy. Internal seals often use HNBR or PTFE for refrigerant compatibility. Manufacturers conduct helium leak tests during final assembly. Components must meet ISO and ARI performance standards. Professional installations require compliance with international codes.

A copper refrigeration valve must withstand vibration. Compressor units generate mechanical pulses during operation. Poorly designed valves can fatigue under repeated movement. Copper’s ductile structure tolerates vibrational stress well. Mounting brackets and stabilizers further absorb motion. Valves installed near compressors feature thicker walls. This helps prevent system shutdown caused by mechanical failure.

Chemical Properties Of Copper Refrigeration Valve

| Chemical Element | Symbol | Percentage (%) | Description |

|---|---|---|---|

| Copper | Cu | ≥ 99.90% | Primary material providing conductivity, corrosion resistance, and durability. |

| Phosphorus | P | 0.015–0.040% | Improves deoxidation and enhances brazability in refrigeration systems. |

| Lead | Pb | ≤ 0.005% | Minimizes harmful contamination; necessary for plumbing safety and purity. |

| Iron | Fe | ≤ 0.05% | Trace element; excessive content may reduce ductility and corrosion resistance. |

| Oxygen | O | 0.001–0.040% | Residual oxygen during casting; controlled to prevent oxide formation. |

| Nickel | Ni | ≤ 0.05% | Improves thermal endurance and prevents high-temperature scaling. |

| Zinc | Zn | ≤ 0.03% | Trace presence; excessive content lowers corrosion resistance in refrigerants. |

| Total Impurities | - | ≤ 0.10% | Maintains material stability and long-term refrigeration performance. |

Copper valves support environmentally friendly refrigerants. Modern systems use R600a, CO₂, and low-GWP alternatives. Valve geometry adapts to different molecular behaviors. Copper surfaces exhibit minimal chemical interaction. This prevents refrigerant decomposition over time. Sustainable HVAC technologies rely on material compatibility. Copper remains a preferred green refrigeration solution.

Maintenance of copper refrigeration valves is straightforward. Visual inspection identifies wear or corrosion early. Replacing seals or packing rings can restore full function. Lubricated seats minimize friction during opening and closing. Routine testing verifies pressure stability at operating ranges. Technicians keep a record of valve performance metrics. Predictive maintenance reduces accidental breakdowns.

Industrial refrigeration facilities use multiple valve stages. Primary valves isolate compressors or evaporators. Secondary valves regulate distribution to cooling branches. Copper units integrate easily within modular piping frameworks. Uniform sizing reduces spare parts inventory. Operators benefit from simplified repairs and upgrades. Scalability is essential for large food storage networks.

Mechanical properties Properties Of Copper Refrigeration Valve

| Mechanical Property | Unit | Typical Value | Description |

|---|---|---|---|

| Tensile Strength | MPa | 220 – 260 | Ability of copper valve material to withstand pulling forces without fracture. |

| Yield Strength | MPa | 60 – 90 | Stress limit at which permanent deformation begins under pressure cycles. |

| Elongation | % | 30 – 45 | Ductility of copper; helps absorb vibration and prevents cracking. |

| Hardness (HB) | HB | 45 – 80 | Resistance to wear, scratches, and mechanical surface damage. |

| Density | g/cm³ | 8.90 | Material mass per volume; stable density helps maintain valve dimensions. |

| Thermal Conductivity | W/m·K | 385 – 400 | Fast heat transfer enables efficiency in refrigeration temperature changes. |

| Fatigue Strength | MPa | 95 – 100 | Resistance to repeated stress and vibration during compressor operation. |

| Coefficient of Thermal Expansion | µm/m·K | 16.5 – 17.6 | Expansion rate of copper under temperature changes; prevents leak formation. |

Application:

- Electrical Industry

- HVAC Industry

- Ball Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Frequently Asked Questions (FAQs)

1. What is a Copper Refrigeration Valve?

A copper refrigeration valve is a control component installed in HVAC and refrigeration systems to regulate, isolate, and monitor refrigerant flow. It ensures safe operation, pressure balance, and service access.

2. Why is copper used for refrigeration valves?

Copper is chosen for its high corrosion resistance, thermal conductivity, excellent brazing capability, and durability. It performs reliably in low-temperature and high-pressure refrigeration conditions.

3. Are copper refrigeration valves suitable for all refrigerants?

Yes, they work with most common refrigerants such as R134a, R22, R404A, R407C, R410A, R600a, and CO₂. Material compatibility and sealing type should be verified based on the specific refrigerant.

4. How are copper refrigeration valves installed?

These valves are typically installed using brazing, welding, or flare connections. Brazed joints offer permanent leak-proof connections, making them ideal for commercial and industrial refrigeration systems.

5. What types of copper refrigeration valves are available?

Common types include ball valves, service valves, Schrader valves, needle valves, and expansion valves. Each type serves a specific function like shutoff, pressure testing, regulation, or refrigerant charging.

6. Can copper refrigeration valves handle high pressure?

Yes. High-quality copper valves can withstand high working pressures, often exceeding 4.0 MPa (580 PSI), depending on design, body thickness, and sealing materials.

7. Do copper refrigeration valves require maintenance?

Routine inspection is recommended. Maintenance includes checking seals, pressure integrity, leaks, and vibration-related wear. Proper servicing extends valve life and system performance.

8. Are copper refrigeration valves suitable for food storage systems?

Yes. Copper is hygienic, stable, and compatible with low-temperature refrigeration, making it suitable for cold rooms, supermarket freezers, and food preservation systems.

9. What sealing materials are used in these valves?

Seals typically include HNBR, PTFE, or FKM. The choice depends on pressure level, refrigerant type, and temperature exposure in the HVAC or refrigeration application.

10. How do I choose the correct copper refrigeration valve size?

Valve size should match refrigerant line diameter, operating pressure, flow rate, and system capacity. Proper sizing prevents pressure drop, leakage, and cooling inefficiencies.

Our valuable Products

Brass-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Check-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Brass-Valves-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Brass-Water-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Valve-Fittings-Manufacturer-Stockist-Exporter.html,

Copper-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Check-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Refrigeration-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Forged-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Forged-Copper-Valve-Manufacturer-Stockist-Exporter.html,

High-Pressure-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Lead-Free-Brass-valve-Manufacturer-Stockist-Exporter.html,

Countries we have exported our products to:

manufacturer stockist and Valve of Copper Refrigeration Valve in mumbai,manufacturer stockist and Valve of Copper Refrigeration Valve in India,manufacturer stockist and Valve of Copper Refrigeration Valve in United Arab Emirates,manufacturer stockist and Valve of Copper Refrigeration Valve in Saudi Arabia,manufacturer stockist and Valve of Copper Refrigeration Valve in Kuwait,manufacturer stockist and Valve of Copper Refrigeration Valve in Bahrain Qatar,manufacturer stockist and Valve of Oman, manufacturer stockist and Valve of Copper Refrigeration Valve in USA, Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.