- Call Us for help!

- +91 9819742205

- Mail Us

- Brasslinkinternational@gmail.com

Manufacturer,Stockist and Exporter of Copper Plumbing Valve

Copper plumbing valves are essential components in modern water supply systems, ensuring smooth control of water flow. Known for their corrosion resistance, durability, and reliability, copper valves are widely used in residential, commercial, and industrial plumbing applications. These valves provide precise regulation and longevity, making them a preferred choice among plumbers and engineers. Copper’s natural antimicrobial properties also reduce the risk of bacterial growth, enhancing the safety of potable water systems. Their easy installation and compatibility with various piping materials add to their popularity. Copper plumbing valves are available in a wide range of sizes and types to suit diverse needs. Manufacturers focus on maintaining high-quality standards to meet international certifications. With efficient flow control, they help reduce water wastage and maintain optimal system performance.

The manufacturing process of copper plumbing valves involves precision casting and machining to ensure leak-free operation. Each valve is tested rigorously to meet performance standards under high pressure and temperature conditions. Copper valves are resistant to scaling and sediment buildup, which prolongs their service life. They are commonly used in hot and cold water systems due to their thermal conductivity and structural integrity. The aesthetic appeal of copper also makes it suitable for visible plumbing installations in luxury interiors. Maintenance is minimal, as copper valves rarely corrode or require replacement. These valves are designed to handle high flow rates without compromising on safety. Additionally, copper plumbing valves are environmentally friendly, being fully recyclable.

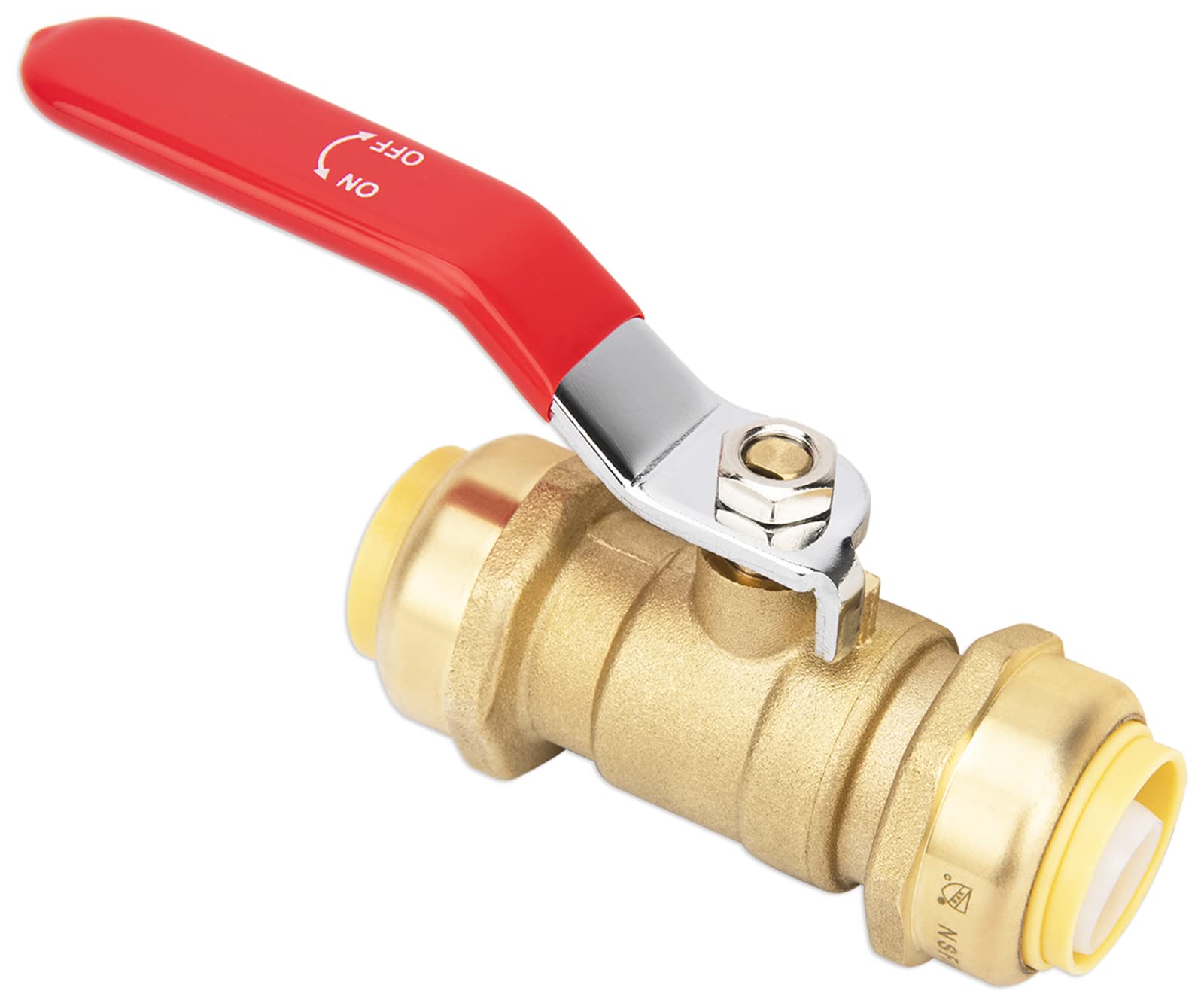

Copper plumbing valves come in several types, including ball valves, gate valves, check valves, and stop valves. Ball valves offer tight shut-off and are ideal for on/off control applications. Gate valves allow for gradual opening and closing, suitable for regulating flow in large pipelines. Check valves prevent backflow, protecting plumbing systems from contamination. Stop valves provide localized control for specific fixtures or equipment. Each type is engineered to ensure smooth operation and long-term reliability. The choice of valve depends on the system’s pressure, flow requirements, and installation environment. Copper valves are also compatible with various joining methods, such as soldering, compression, and push-fit connections. This versatility ensures they can be adapted to both new installations and retrofitting projects.

The advantages of copper plumbing valves extend beyond performance. Copper is naturally resistant to corrosion from water and most chemicals commonly found in plumbing systems. This resistance ensures minimal maintenance and a longer operational life compared to alternative materials. Copper valves also maintain structural integrity under varying temperatures and pressures. Their antimicrobial properties make them especially suitable for potable water applications. Furthermore, copper plumbing valves offer consistent and reliable sealing, preventing leaks that could lead to water damage. They are also recyclable, aligning with sustainable building practices. Copper’s aesthetic appeal enhances exposed plumbing systems, blending functionality with visual design. The durability and reliability of copper valves make them a preferred choice for professional plumbers worldwide.

In industrial applications, copper plumbing valves are valued for their robustness and ability to withstand harsh operating conditions. High-pressure steam, hot water, and chemical processes benefit from copper’s mechanical strength and thermal conductivity. Copper valves are often used in HVAC systems, manufacturing plants, and food processing facilities. Their resistance to corrosion and scaling ensures uninterrupted operation. Additionally, these valves can handle frequent operation without wear, reducing downtime and maintenance costs. The precise engineering of copper valves allows for accurate flow regulation, contributing to energy efficiency in industrial systems. Manufacturers provide detailed specifications, including pressure ratings and temperature limits, ensuring proper selection for each application. Copper plumbing valves are also compliant with international plumbing codes and standards.

Residential plumbing systems benefit significantly from copper plumbing valves due to their reliability and ease of use. Homeowners appreciate the low maintenance requirements and long service life. Copper valves are suitable for hot and cold water lines, including kitchen and bathroom fixtures. They ensure smooth operation with minimal effort, even after years of use. Copper’s antimicrobial properties contribute to healthier water supply systems. In addition, their installation is straightforward, reducing labor costs and installation time. Copper valves are available in various finishes, such as polished, brushed, or antique, complementing interior design. They are designed to fit standard pipe sizes, ensuring seamless integration into existing plumbing systems. Copper valves also provide leak-proof connections, protecting homes from water damage.

The reliability of copper plumbing valves is enhanced through rigorous quality control measures during manufacturing. Each valve undergoes pressure testing, leak testing, and dimensional inspections to ensure compliance with industry standards. Copper valves meet or exceed certifications such as ASTM, ISO, and EN standards. This ensures they perform effectively in diverse environmental conditions. The valves are engineered to resist mechanical stress, thermal expansion, and internal pressure fluctuations. High-quality copper valves provide smooth operation without sticking or jamming. They also offer resistance to galvanic corrosion when connected to other metals. Continuous improvements in casting and machining technology have resulted in valves with tighter tolerances and superior sealing performance. Copper plumbing valves combine traditional durability with modern engineering precision.

Maintenance of copper plumbing valves is simple, thanks to their corrosion-resistant properties. Regular inspection ensures optimal performance and early detection of any wear or damage. Cleaning copper valves is straightforward and requires minimal effort. Lubrication of moving parts is rarely needed due to their smooth mechanical operation. If installed correctly, copper valves can last several decades without replacement. Replacement components, if ever required, are widely available in the market. Copper plumbing valves maintain performance even in hard water conditions, minimizing scale buildup. They are also compatible with water treatment systems, ensuring safe potable water supply. Proper installation and periodic inspection further enhance their longevity.

Specification Of Copper Plumbing Valve

| Specification | Details |

|---|---|

| Material | Copper Alloy (C69300, C37700, or similar) |

| Type | Ball Valve, Gate Valve, Check Valve, Stop Valve |

| Size Range | 1/4" to 4" (DN8 to DN100) |

| Pressure Rating | PN16 / 16 Bar (up to 232 psi) |

| Temperature Range | -20°C to 120°C (-4°F to 248°F) |

| Connection Type | Solder, Compression, Threaded (NPT/BSP), Push-fit |

| Standards Compliance | ASTM B75, ISO 9001, EN 1254, ASME B16.18 |

| Flow Coefficient (Cv) | Varies with size and type, typically 2–50 |

| Operation | Manual Lever, Gear Operated, or Automated Actuator |

| Applications | Residential, Commercial, Industrial, HVAC, Water Supply Systems |

Copper plumbing valves contribute to energy efficiency in plumbing systems. Their high thermal conductivity helps maintain temperature stability in hot water lines. This reduces energy loss and improves system efficiency. Copper valves also provide precise flow control, allowing systems to operate at optimal pressures. Accurate regulation prevents water hammer and pressure surges that can damage plumbing networks. By minimizing leaks and wastage, copper valves support sustainable water usage practices. Industrial applications also benefit from reduced operational costs due to energy-efficient valve operation. In addition, copper valves are environmentally friendly, being recyclable at the end of their service life. Their performance and eco-friendliness make them a popular choice among builders and engineers.

Copper plumbing valves are designed to provide quiet operation. Their smooth internal surfaces reduce turbulence and minimize noise caused by water flow. This makes them suitable for residential buildings, hospitals, and hotels where noise reduction is important. High-quality copper valves maintain consistent performance without vibration or rattling. Ball and gate valve designs ensure minimal pressure drop across the system. Check valves prevent reverse flow, which can create water hammer and noise. Copper’s inherent damping properties also contribute to quieter operation. Engineers recommend copper valves for projects where acoustic performance is critical. The combination of durability, efficiency, and silent operation makes them ideal for modern plumbing applications.

Customization options are available for copper plumbing valves to meet specific project requirements. Manufacturers offer valves in different sizes, pressure ratings, and connection types. Special coatings or finishes can be applied for aesthetic or protective purposes. Valves can also be tailored for specific applications, such as high-temperature systems or corrosive environments. Customized copper valves ensure compatibility with unique plumbing layouts. Technical support is often provided to assist in selecting the right valve type for a project. This flexibility allows engineers and plumbers to design efficient and reliable water systems. Copper valves can also be integrated with automation systems for remote operation in industrial facilities. The adaptability of copper valves contributes to their widespread use worldwide.

Chemical Properties Of Copper Plumbing Valve

| Element | Composition (%) |

|---|---|

| Copper (Cu) | 58 – 70% |

| Zinc (Zn) | 30 – 42% |

| Lead (Pb) | ≤ 0.05 – 3% |

| Iron (Fe) | ≤ 0.3% |

| Nickel (Ni) | ≤ 0.2% |

| Tin (Sn) | ≤ 0.5% |

| Other Elements | Trace amounts as per ASTM/EN standards |

Copper plumbing valves are widely available through reputable suppliers and distributors. Professional plumbing companies prioritize sourcing high-quality copper valves to ensure system reliability. OEM and certified products provide assurance of performance and compliance with international standards. Bulk orders are often available for large construction projects or industrial applications. Suppliers also provide technical documentation, including installation guidelines, maintenance tips, and performance specifications. Availability of replacement parts ensures long-term system maintenance. The wide distribution network ensures quick delivery and support for any issues. Access to high-quality copper valves facilitates smooth project execution. Customers can choose valves based on size, type, and pressure rating.

Cost-effectiveness is another benefit of copper plumbing valves. While the initial investment may be higher than some alternatives, their longevity and low maintenance reduce overall lifecycle costs. Fewer replacements and repairs result in long-term savings for residential, commercial, and industrial projects. Energy efficiency also contributes to reduced operational costs. Copper valves’ durability minimizes system downtime and maintenance labor. They offer consistent performance over decades, making them a reliable investment. Sustainable manufacturing and recyclability add environmental value, aligning with modern building practices. Homeowners and engineers recognize copper valves as a cost-effective, high-performance solution. Their combined reliability, efficiency, and sustainability make them a smart choice.

Copper plumbing valves are compatible with modern water systems and emerging technologies. They integrate easily with smart plumbing solutions for monitoring water flow, pressure, and temperature. Automated control systems can operate copper valves remotely, improving system efficiency. Integration with IoT-enabled systems enhances water conservation and energy management. Copper valves maintain performance even in high-tech plumbing networks. Their precision engineering ensures compatibility with sensors and actuators. Smart building designs increasingly incorporate copper valves for durability and control. Continuous innovation in valve design ensures copper remains relevant for advanced plumbing solutions. Their adaptability ensures long-term usefulness in modern infrastructure.

Mechanical properties Properties Of Copper Plumbing Valve

| Property | Value / Range |

|---|---|

| Tensile Strength | 300 – 450 MPa |

| Yield Strength | 200 – 300 MPa |

| Elongation | 10 – 25% |

| Hardness (Brinell) | 60 – 120 HB |

| Density | 8.4 – 8.9 g/cm³ |

| Melting Point | 900 – 940 °C |

| Pressure Rating | Up to 16 Bar (PN16) |

| Impact Strength | Moderate, depends on alloy composition |

| Thermal Conductivity | 110 – 120 W/m·K |

| Corrosion Resistance | Excellent in potable water and moderate industrial environments |

Application:

- Electrical Industry

- HVAC Industry

- Plumbing Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Frequently Asked Questions (FAQs)

1. What are copper plumbing valves used for?

Copper plumbing valves are used to control the flow of water in residential, commercial, and industrial plumbing systems. They ensure smooth operation, prevent leaks, and maintain water quality.

2. What types of copper valves are available?

The common types include ball valves, gate valves, check valves, and stop valves. Each type serves a specific function, such as on/off control, flow regulation, or backflow prevention.

3. What sizes and pressure ratings are available?

Copper plumbing valves are available in sizes ranging from 1/4" to 4" (DN8 to DN100) with pressure ratings up to PN16 (16 bar). Specific sizes and ratings depend on the valve type and application.

4. Are copper valves resistant to corrosion?

Yes, copper valves are naturally corrosion-resistant, making them ideal for potable water systems and other plumbing applications. They also resist scaling and bacterial growth.

5. Can copper plumbing valves be used with hot water?

Yes, they are suitable for both hot and cold water systems. Most copper valves can handle temperatures up to 120°C (248°F) without compromising performance.

6. How are copper valves installed?

Copper plumbing valves can be installed using soldering, compression fittings, threaded connections (NPT/BSP), or push-fit systems. Proper installation ensures leak-free operation and long service life.

7. How long do copper plumbing valves last?

With proper installation and maintenance, copper valves can last 20–50 years or more due to their durability, corrosion resistance, and robust mechanical properties.

8. Are copper valves environmentally friendly?

Yes, copper valves are fully recyclable and reduce water wastage through reliable flow control. They also require minimal maintenance, which contributes to sustainability.

Our valuable Products

Brass-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Check-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Brass-Valves-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Brass-Water-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Valve-Fittings-Manufacturer-Stockist-Exporter.html,

Copper-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Check-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Refrigeration-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Forged-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Forged-Copper-Valve-Manufacturer-Stockist-Exporter.html,

High-Pressure-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Lead-Free-Brass-valve-Manufacturer-Stockist-Exporter.html,

Countries we have exported our products to:

manufacturer stockist and Valve of Copper Plumbing Valve in mumbai,manufacturer stockist and Valve of Copper Plumbing Valve in India,manufacturer stockist and Valve of Copper Plumbing Valve in United Arab Emirates,manufacturer stockist and Valve of Copper Plumbing Valve in Saudi Arabia,manufacturer stockist and Valve of Copper Plumbing Valve in Kuwait,manufacturer stockist and Valve of Copper Plumbing Valve in Bahrain Qatar,manufacturer stockist and Valve of Oman, manufacturer stockist and Valve of Copper Plumbing Valve in USA, Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.