- Call Us for help!

- +91 9819742205

- Mail Us

- Brasslinkinternational@gmail.com

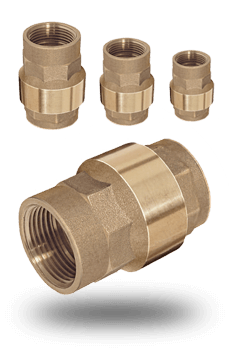

Manufacturer,Stockist and Exporter of Lead Free Brass Valve

Lead free brass valves represent a modern response to increasingly strict safety standards in plumbing and potable water systems. Unlike conventional brass valves that may contain higher lead percentages, these valves limit lead content to meet regulatory guidelines. The material composition ensures compatibility with drinking water, ensuring user safety in domestic and industrial setups. Manufacturers deploy advanced forging and casting processes to guarantee exceptional reliability. Lead free brass valves are widely used in kitchens, bathrooms, heating systems, and irrigation networks. Their corrosion resistance and durability offer long service life even under continuous operation. As regulatory awareness grows, lead free brass valves have become the preferred option worldwide.

Lead exposure through water systems has been a documented concern for many decades. Even trace amounts of lead dissolved into drinking water can cause long-term health complications. Lead free brass valves restrict harmful contaminants, keeping water flow clean and safe. Modern standards like NSF/ANSI 61 and 372 strictly define acceptable levels in plumbing materials. Engineers recreate alloy compositions to maintain mechanical strength while reducing hazardous metals. Consumers benefit from health protection while businesses meet compliance demands. The transition to lead free valves is not only ethical but also economically beneficial in the long term.

Lead free brass typically uses copper-zinc alloys with minimal allowable lead content below defined thresholds. Elemental additives like silicon, phosphorous, or bismuth may be incorporated for machinability. These additives help maintain structure integrity without compromising health safety. Properties such as tensile strength, hardness, and thermal stability are preserved. The alloy composition performs efficiently in wet environments with minimal degradation. Modern material science ensures resistance to dezincification or stress corrosion cracking. Lead free brass remains one of the most trusted metals for fluid control systems.

Lead free brass valves are engineered with precision-machined bodies and robust sealing components. Internal flow chambers are optimized to reduce turbulence, preserving smooth discharge. Forged construction techniques enhance density, resulting in improved mechanical performance. Ball, gate, globe, check, compression, and angle designs suit various application needs. Advanced sealing technologies provide tight shut-off performance under fluctuating pressures. Threads and connection points are machined to industry standards for universal compatibility. Valve geometry balances compact form with operational strength to support long-term reliability.

Lead free brass valves are integral in residential drinking water installations. They regulate flow to faucets, water heaters, filtration systems, and dishwasher circuits. Municipal water supply lines frequently use them due to their long-term health compliance. In hospitals, hotels, and schools, they ensure water purity without compromising efficiency. Plumbers rely on them for service connections, meter installations, and system balancing. Lead free brass valves function reliably under continuous pressure variations. Their chemical stability helps preserve water taste and quality during prolonged circulation.

Beyond residential systems, lead free brass valves are widely used in commercial installations. Heating, cooling, and HVAC networks benefit from their corrosion-resistant performance. Manufacturers use them in food processing environments due to safety certifications. High-pressure system compatibility increases their adoption in thermal plants and chillers. Their resistance to scaling reduces maintenance intervals in large infrastructures. Lead free brass valves can handle adaptable temperature ranges confidently. Businesses adopt them to meet environmental and compliance-driven procurement standards.

Lead free brass valves excel in systems exposed to moisture, chemicals, or temperature fluctuations. Their structural integrity prevents internal fatigue under repeated cycling. Even in chlorinated systems, they resist surface attacks and material breakdown. They show higher tolerance to dezincification compared to standard brass valves. Heat transfer properties maintain reliability during thermal expansion and contraction. Precision machining ensures uniform sealing, preventing drip leaks or pressure losses. Their endurance reduces replacement frequency and overall lifecycle costs.

Engineers tune lead free brass valve designs for optimal hydraulic properties. Ball valves enable full-bore passage, minimizing friction loss and energy waste. Gate and globe valves provide flexible throttling control in variable applications. Smooth internal contours reduce cavitation risk in high-pressure circuits. Compression-style designs offer tamper-free assembly without soldering. Lead free brass maintains dimensional stability, ensuring repeatable flow performance. System designers appreciate the balance of compact size and large flow capacity.

Specification Of Lead Free Brass Valve

| Parameter | Specification |

|---|---|

| Material Grade | Lead Free Brass (≤ 0.25% Pb) — e.g., C69300 / CW511L / ECO Brass |

| Valve Type | Ball, Gate, Globe, Check, Compression, Angle |

| Size Range | 1/4" to 4" (DN8 – DN100) |

| Pressure Rating | Up to 600 PSI (depending on model and connection) |

| Temperature Range | -20°C to +180°C (with suitable seals) |

| Body Finish | Natural Brass / Nickel Plated / Chrome Plated |

| Connection Type | NPT / BSP / Sweat / Compression / Press / Flare |

| Sealing Material | PTFE, EPDM, NBR (depending on application) |

| Flow Characteristics | Full Port / Standard Port (as model applicable) |

| Working Medium | Potable Water, Hot Water, Air, Non-Corrosive Liquids |

| Surface Treatment | Passivated / Polished / Coated for corrosion protection |

| Manufacturing Process | Forged / Cast / CNC Machined |

| Standards Compliance | NSF/ANSI 61 & 372, WRAS, RoHS, EU Drinking Water |

| Testing | 100% Pressure Tested — Leak & Torque Verified |

| Application | Residential Plumbing, Commercial Systems, HVAC, Irrigation |

Lead free brass valves can be produced through forging, casting, or CNC machining. Forged bodies provide high-density grain alignment for enhanced durability. Casting allows intricate geometries while reducing material consumption. CNC machining provides tight tolerances in sealing, threading, and port shaping. Surface finishing eliminates burrs and imperfections that might degrade performance. Automated testing procedures verify pressure resistance, leakage, and functional reliability. Manufacturers often follow ISO-certified quality programs for global export compliance.

Lead free brass valves must meet strict industry standards to be accepted in public networks. Certifications like NSF/ANSI 61 or 372 confirm safe material composition. WATERMARK, WRAS, and EU directives define acceptable contaminant thresholds. Regulatory labeling ensures transparency for installers and buyers. Environmental policies encourage adoption in plumbing codes worldwide. Manufacturers display compliance documentation to streamline auditing. Certified valves guarantee consistent health safety performance over years of use.

Lead free brass valves should be installed by trained professionals. Threads must be cleaned to prevent unwanted debris or sealing failure. Sealing tape or approved sealant is applied according to manufacturer recommendations. Installers tighten with calibrated force to avoid thread distortion or cracking. Valve orientation should match the directional flow marking when applicable. After installation, the system is pressure-tested for leakage and stability. Proper installation safeguards system integrity and ensures water quality.

Chemical Properties Of Lead Free Brass Valve

| Chemical Element | Symbol | Typical Composition (%) | Notes / Purpose |

|---|---|---|---|

| Copper | Cu | 57.0 – 65.0 | Primary base metal — strength, corrosion resistance. |

| Zinc | Zn | 32.0 – 40.0 | Improves mechanical strength & machinability. |

| Silicon | Si | 1.0 – 3.0 | Lead substitute — increases machining capability. |

| Manganese | Mn | 0.1 – 1.0 | Enhances toughness & wear resistance. |

| Phosphorus | P | 0.01 – 0.35 | Improves castability & deoxidation stability. |

| Bismuth | Bi | 0.02 – 1.5 | Alternative to lead — supports machining. |

| Iron | Fe | 0.1 – 1.2 | Increases tensile strength and hardness. |

| Lead | Pb | ≤ 0.25 | Meets lead-free standards (NSF/ANSI 372). |

Regular inspection extends the service life of lead free brass valves. Periodic rotation prevents internal sticking due to mineral buildup. Filters or strainers help protect valves from particulate contamination. Minor leaks are usually remedied by adjusting seals or replacing O-rings. Professional technicians should evaluate corrosion signs or flow restriction. Timely maintenance lowers costs while maintaining user safety. Well-maintained valves can last many years in demanding environments.

Lead free brass promotes eco-conscious construction and manufacturing. By eliminating hazardous metals, waste handling becomes significantly safer. Reduced contamination risk protects freshwater resources and aquatic ecosystems. Regulations incentivize sustainable materials with long service lifespans. Manufacturers optimize alloy recycling, reducing overall production footprint. Lead free brass valves contribute to greener infrastructure development globally. Their usage signals industry-wide progress toward cleaner engineering practices.

Although initial cost may exceed traditional brass, long-term value is superior. Fewer health risks reduce legal liabilities and system remediation expenses. Durability limits replacement frequency, lowering total cost of ownership. Stable performance prevents losses from leaks, flow inefficiency, or downtime. Lead free compliance expands markets across regulated regions. Commercial buyers benefit from increased product credibility and certification access. Economically, the investment rewards both end-users and infrastructure planners.

Mechanical properties Properties Of Lead Free Brass Valve

| Mechanical Property | Unit | Typical Value | Remarks |

|---|---|---|---|

| Tensile Strength | MPa | 400 – 520 | Indicates overall loading capacity and structural strength. |

| Yield Strength (0.2% Offset) | MPa | 220 – 380 | Defines elastic limit under fluid system pressure. |

| Elongation | % | 15 – 30 | Shows ductility and deformation capability. |

| Hardness | HB (Brinell) | 85 – 120 | Higher hardness offers wear resistance and sealing reliability. |

| Impact Strength | J | ≥ 30 | Ability to withstand sudden force or system load spikes. |

| Density | g/cm³ | 8.3 – 8.6 | Material mass per volume; affects flow and thermal behavior. |

| Thermal Conductivity | W/m·K | 105 – 120 | Ensures performance in hot water or HVAC environments. |

| Coefficient of Thermal Expansion | µm/m·°C | 19 – 21 | Important for temperature cycling and sealing stability. |

Application:

- Electrical Industry

- HVAC Industry

- Ball Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Frequently Asked Questions (FAQs)

1. What is a lead-free brass valve?

A lead-free brass valve is manufactured using a special brass alloy with a maximum of 0.25% lead content, ensuring safe usage for potable water systems and compliance with international drinking water standards.

2. Why should I choose a lead-free brass valve?

Lead-free brass valves prevent harmful lead contamination in drinking water. They improve health safety, meet building regulations, and are widely accepted in residential, commercial, and industrial installations.

3. Where are lead-free brass valves commonly used?

They are used in potable water lines, filtration systems, kitchens, bathrooms, irrigation, HVAC pipelines, hospitals, and food processing applications where lead safety is essential.

4. What certifications apply to lead-free brass valves?

Lead-free valves typically comply with NSF/ANSI 61, NSF/ANSI 372, WRAS, RoHS, and EU Drinking Water directives. These certifications ensure that the material and design are safe for human consumption.

5. Do lead-free brass valves have the same performance as traditional brass?

Yes. Modern alloy formulations preserve mechanical strength, corrosion resistance, and durability. In many cases, lead-free valves perform better due to improvements in dezincification resistance.

6. Are lead-free brass valves suitable for hot water systems?

Lead-free brass valves can operate efficiently in hot and cold water environments. They handle wide temperature ranges when paired with appropriate sealing materials such as EPDM or PTFE.

Our valuable Products

Brass-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Check-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Brass-Valves-Manufacturer-Stockist-Exporter.html,

Brass-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Brass-Water-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-and-Brass-Valve-Fittings-Manufacturer-Stockist-Exporter.html,

Copper-Ball-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Check-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Compression-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Gate-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Globe-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Industrial-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Plumbing-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Refrigeration-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Exporter-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Manufacturer-Stockist-Exporter.html,

Copper-Valve-Supplier-Manufacturer-Stockist-Exporter.html,

Forged-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Forged-Copper-Valve-Manufacturer-Stockist-Exporter.html,

High-Pressure-Brass-Valve-Manufacturer-Stockist-Exporter.html,

Lead-Free-Brass-valve-Manufacturer-Stockist-Exporter.html,

Countries we have exported our products to:

manufacturer stockist and Valve of Lead Free Brass Valve in mumbai,manufacturer stockist and Valve of Lead Free Brass Valve in India,manufacturer stockist and Valve of Lead Free Brass Valve in United Arab Emirates,manufacturer stockist and Valve of Lead Free Brass Valve in Saudi Arabia,manufacturer stockist and Valve of Lead Free Brass Valve in Kuwait,manufacturer stockist and Valve of Lead Free Brass Valve in Bahrain Qatar,manufacturer stockist and Valve of Oman, manufacturer stockist and Valve of Lead Free Brass Valve in USA, Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.